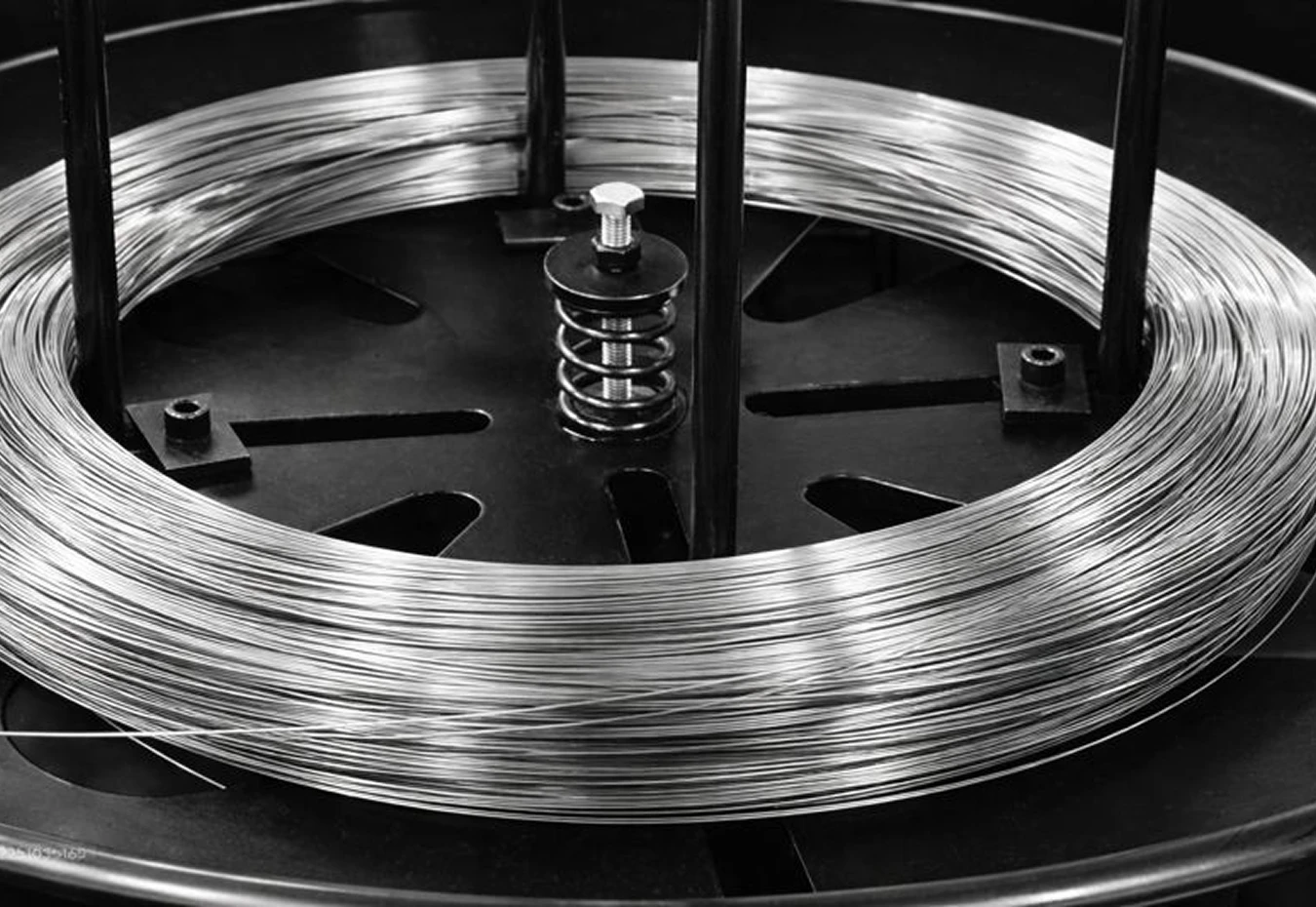

RATANAKAR Wire Private Limited (RWPL) is a reliable manufacturer and supplier of stainless steel alloy wire designed for high-temperature strength, corrosion resistance, and long-term performance. Our SS alloy wire are widely used in demanding industrial environments where standard stainless steel grades may not perform efficiently.

Alloy wire are manufactured by adding elements such as nickel, chromium, molybdenum, or titanium to stainless steel, enhancing heat resistance, oxidation resistance, and mechanical strength. This makes stainless steel alloy wire ideal for critical applications involving extreme temperatures, pressure, and aggressive operating conditions.

Manufacturing & Quality

At RWPL, stainless steel alloy wire are produced using advanced wire drawing and heat-treatment technologies to ensure precise diameter control, consistent chemistry, and superior surface finish. Our in-house manufacturing capabilities include solution annealing, bright annealing, controlled wire drawing, straightening, cutting, and customized packaging.

All SS alloy wire are manufactured under an ISO 9001:2015 quality management system and comply with international standards such as ASTM, DIN, BS, JIS, EN, and IS. Each batch undergoes strict quality inspection to ensure uniform performance and reliability.

We offer stainless steel alloy wire in AISI 304 / 304L, AISI 316 / 316L, AISI 310S, AISI 321 , ER 347, ER 309S high-performance grades suitable for heat-resistant, corrosion-resistant, and pressure-bearing applications.

Key Features of Stainless Steel Alloy Wire

High Heat Resistance – Performs reliably in high-temperature environments

Excellent Corrosion Resistance – Resists oxidation, chemicals, and harsh media

Superior Mechanical Strength – Maintains strength under load and stress

Stable Chemical Composition – Ensures consistent performance

Good Fabricability – Suitable for forming, bending, and welding

Long Service Life – Reduces maintenance and replacement costs

Stainless Steel Alloy Wire Specifications

Wire Diameter Range: As per customer requirement

Grades Available: AISI 304 / 304L, AISI 316 / 316L, AISI 310S, AISI 321 , ER 347, ER 309S

Form Supply: Coil, spool, straight length, or customized

Standards: ASTM, DIN, BS, JIS, EN, IS

Surface Finish: Bright, annealed, or customized

Packaging: Secure, moisture-protected industrial packing

Typical Applications

Our stainless steel alloy wire are used across industries where strength and heat resistance are critical:

Furnaces & Heat Treatment – Heating elements, furnace components

Power Plants – Boilers, heat exchangers, thermal systems

Chemical & Petrochemical – Reactors, processing equipment

Automotive & Aerospace – High-temperature fasteners and components

Industrial Equipment – Springs, meshes, and formed parts

Oil & Gas – High-pressure and heat-resistant applications

Customization & Supply Capabilities

RWPL offers customized SS alloy wire solutions based on grade selection, wire diameter, surface finish, and packaging. Whether your application requires resistance to extreme heat, corrosion, or mechanical stress, our alloy wire are engineered for dependable and consistent performance.

With strong production capacity and timely delivery, RATANAKAR Wire Private Limited supports industrial customers with reliable stainless steel alloy wire solutions for both domestic and international markets.

What are stainless steel alloy wire?

Stainless steel alloy wire are high-performance wires produced by adding elements like nickel, chromium, molybdenum, or titanium to stainless steel, enhancing heat resistance, corrosion resistance, strength, and durability for industrial use.

What is the difference between stainless steel wire and SS alloy wire?

Standard stainless steel wire mainly offer corrosion resistance, while SS alloy wire deliver superior strength, heat resistance, and performance in high-temperature, high-pressure, and aggressive environments, ensuring longer service life.

Which grades of stainless steel alloy wire are available?

Common grades include AISI 304 / 304L, AISI 316 / 316L, AISI 310S, AISI 321 , ER 347, ER 309S, and other heat-resistant or nickel-based alloy grades. Grade selection depends on temperature limits, corrosion exposure, and mechanical requirements.

What industries use stainless steel alloy wire?

Stainless steel alloy wire are widely used in power plants, furnaces, chemical processing, oil & gas, automotive, aerospace, and heat treatment industries where high-temperature and corrosion-resistant materials are required.

Are stainless steel alloy wire suitable for high-temperature applications?

Yes. Stainless steel alloy wire are specifically designed to withstand extreme temperatures and thermal cycling without losing strength or structural integrity, making them ideal for furnace parts, heating elements, and thermal systems.

Can SS alloy wire be customized as per application requirements?

Yes. Stainless steel alloy wire can be customized in terms of grade, wire diameter, surface finish, form (coil, spool, straight length), and packaging to meet specific industrial and engineering requirements.

Which standards do stainless steel alloy wire comply with?

SS alloy wire are manufactured in compliance with ASTM, DIN, BS, JIS, EN, and IS standards, ensuring consistent quality, performance, and global acceptance.