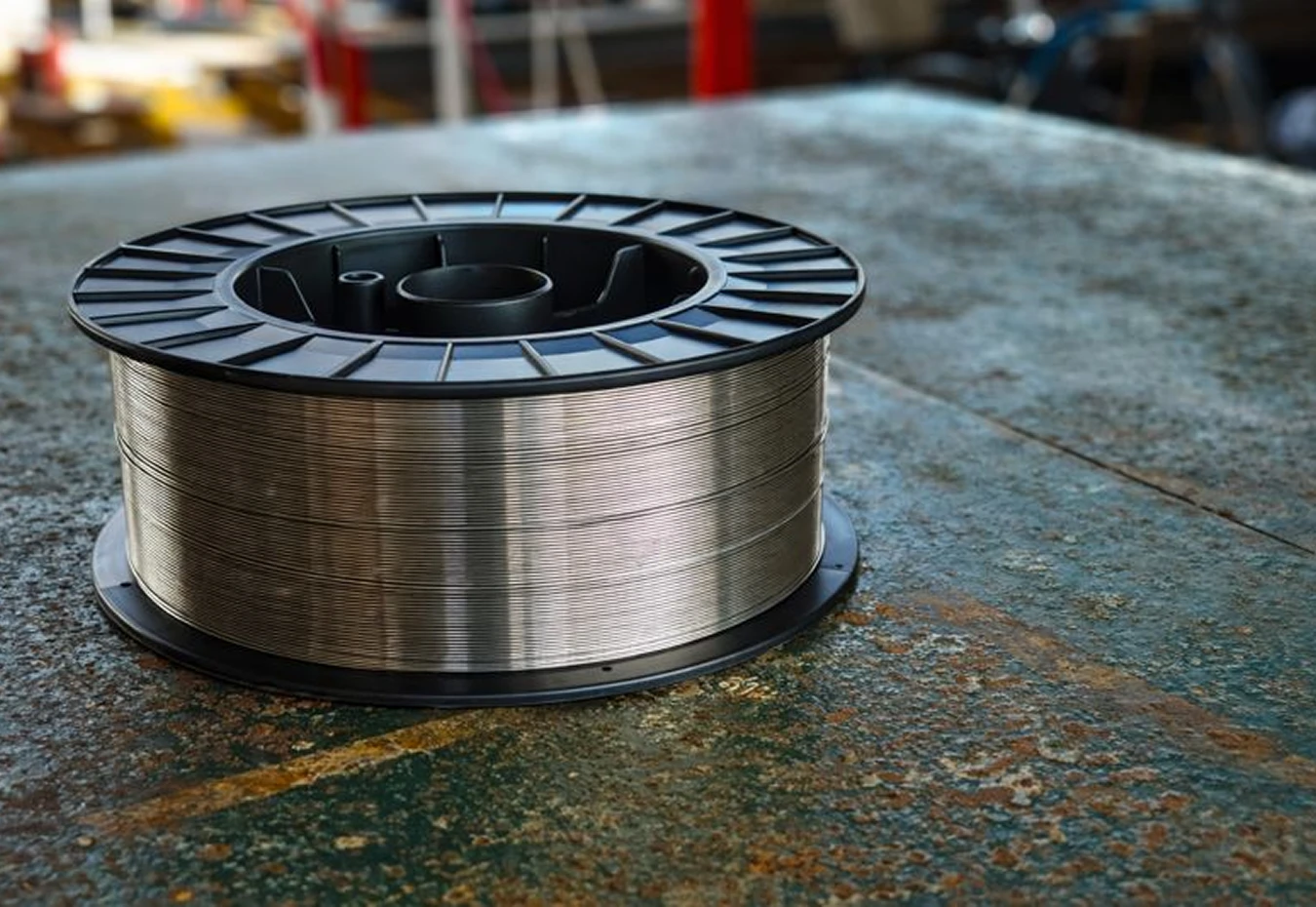

Stainless Steel Welding Wire

RATANAKAR Wire Private Limited (RWPL) is a trusted manufacturer and supplier of stainless steel welding wire engineered for excellent arc stability, strong weld joints, and superior corrosion resistance. Our welding wires are widely used in fabrication, construction, automotive, chemical processing, marine, and heavy engineering industries.

Stainless steel welding wire is produced from premium quality stainless steel wire and designed specifically for MIG, TIG, and automated welding processes. These wires ensure smooth feeding, minimal spatter, and consistent weld quality even in demanding operating conditions.

Manufacturing & Quality

At RWPL, stainless steel welding wire is manufactured using advanced wire drawing, annealing, and surface finishing processes to ensure uniform diameter, controlled chemistry, and clean wire surfaces. Our production facilities are equipped with high-precision drawing machines, controlled heat treatment, and automated spooling systems.

All stainless steel welding wires are manufactured in compliance with ASTM, AWS, DIN, BS, JIS, and ISO standards and are produced under an ISO 9001:2015 certified quality management system. Welding wire grades such as ER 308L, ER 309L, ER 309LSi, ER 310, ER 316L, ER 316LSi, and ER 347, aligned with industry-specific stainless steel grades.

Key Features of Stainless Steel Welding Wire

Excellent Arc Stability – Ensures smooth and controlled welding performance

High Corrosion Resistance – Ideal for aggressive and high-temperature environments

Consistent Wire Diameter – Provides uniform weld penetration and bead appearance

Low Spatter Formation – Improves weld cleanliness and reduces post-weld finishing

High Tensile Strength – Produces strong, durable weld joints

Smooth Surface Finish – Enables uninterrupted wire feeding in manual and automated systems

Stainless Steel Welding Wire Specifications

Wire Diameter Range: As per customer requirement

Grades Available: ER 308L, ER 309L, ER 309LSi, ER 310, ER 316L, ER 316LSi, ER 347

Welding Processes: MIG, TIG, SAW, and automated welding systems

Standards: ASTM, AWS, DIN, BS, JIS, ISO

Surface Finish: Bright, copper-free, or customized finishes

Packaging: Spools, coils, drums, and moisture-protected industrial packing

Typical Applications

Our stainless steel welding wire is widely used across multiple applications across industries due to its strength, weld quality, and corrosion resistance:

Fabrication & Structural Welding – Frames, tanks, pressure vessels

Automotive Industry – Exhaust systems and structural components

Chemical & Process Plants – Pipelines, reactors, storage tanks

Marine & Offshore – Corrosion-resistant welding in coastal environments

Food & Pharmaceutical Equipment – Hygienic and stainless assemblies

Power & Heavy Engineering – Boilers, heat exchangers, and machinery

Customization & Supply Capabilities

RWPL provides custom stainless steel welding wire solutions based on specific welding applications and customer requirements. We offer flexibility in wire grade, diameter, spool size, surface finish, and packaging to meet precise operational needs.

With reliable production capacity, strict quality control, and timely dispatch, RATANAKAR Wire Private Limited ensures consistent supply and dependable performance for both domestic and export markets.

What is stainless steel welding wire used for?

Stainless steel welding wire is used in MIG, TIG, and automated welding applications to create strong, corrosion-resistant weld joints in industrial, marine, and structural components.

Which grades of stainless steel welding wire are available?

RWPL offers welding wire in ER 308L, ER 309L, ER 309LSi, ER 310, ER 316L, ER 316LSi, ER 347 grades depending on welding and corrosion resistance requirements.

Is stainless steel welding wire suitable for MIG and TIG welding?

Yes. Our stainless steel welding wire is specifically designed for smooth feeding and stable arc performance in both MIG and TIG welding processes.

Can RWPL supply customized stainless steel welding wire?

Yes. We provide customization in wire diameter, grade, spool size, surface finish, and packaging based on customer specifications.

How does RATANAKAR ensure the quality of stainless steel welding wire?

Each batch undergoes chemical analysis, tensile testing, diameter inspection, and surface quality checks under ISO 9001:2015 standards.