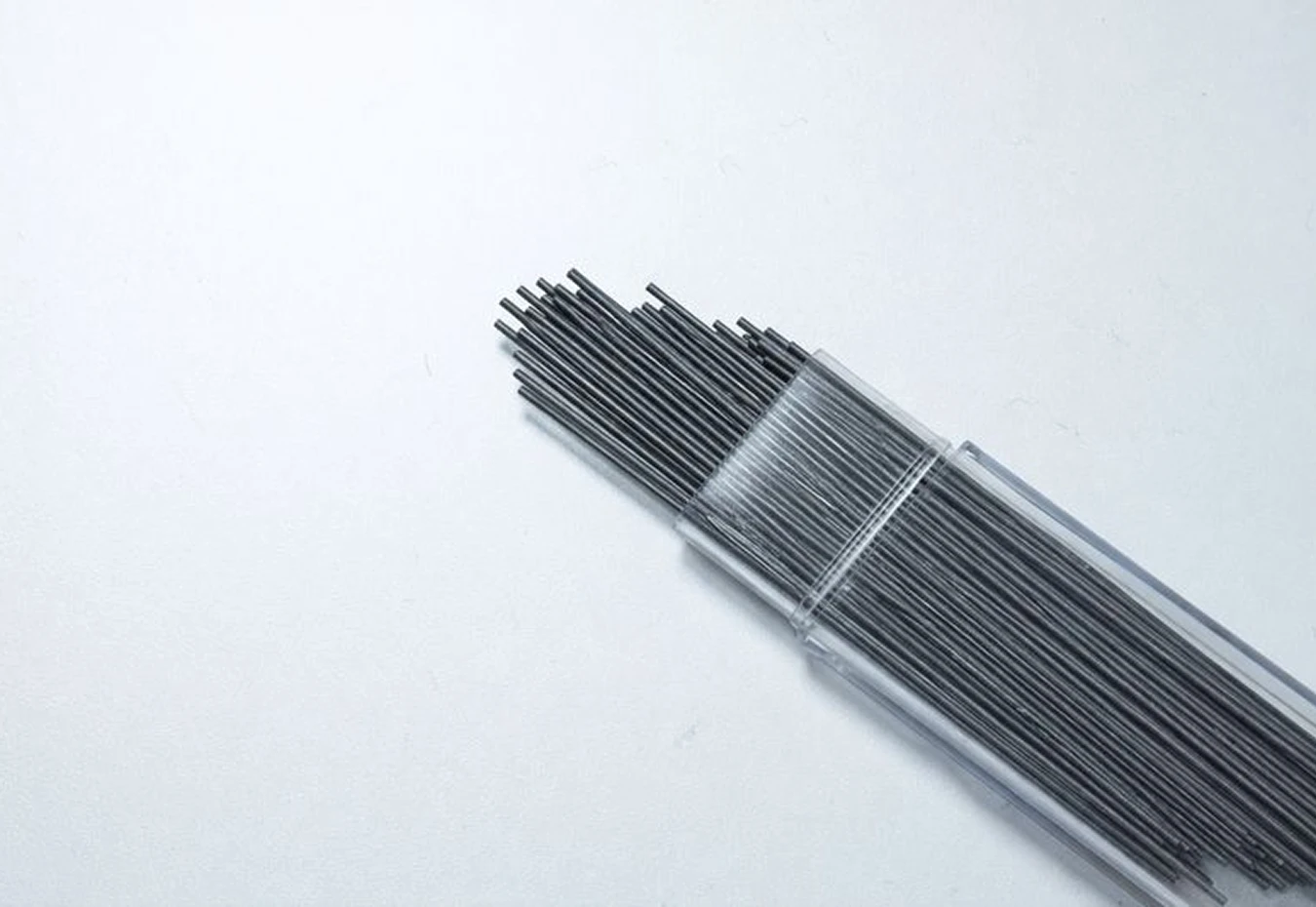

Stainless Steel Filler Wire

RATANAKAR Wire Private Limited (RWPL) is a trusted manufacturer and supplier of SS Filler Wire engineered for strong weld integrity, consistent deposition, and excellent corrosion resistance. Our stainless steel filler wire are widely used in fabrication, pressure vessels, piping, automotive, chemical, oil & gas, and heavy engineering applications.

SS Filler Wire is used during welding to fill joints and ensure high-strength, crack-free welds using stainless steel welding wire.Manufactured from high-purity stainless steel, our filler wires deliver smooth weld flow, uniform bead appearance, and long-term performance even in demanding service conditions.

Manufacturing & Quality

At RWPL, stainless steel filler wire are produced using advanced wire drawing and finishing technologies to ensure accurate diameter control, smooth surface finish, and stable welding performance. Our in-house facilities include solution annealing, bright annealing, precision drawing, straightening, and cutting.

All SS filler wire products are manufactured in compliance with ASTM, AWS, DIN, BS, JIS, NACE, and GOST standards and follow a robust ISO 9001:2015 quality management system. Each batch is tested to ensure consistent chemistry, mechanical strength, and weldability.

We offer SS filler wire in ER 308L, ER 309L, ER 310, ER 316, ER 316L, ER 347 and other compatible grades to suit various base metals and welding conditions.

Key Features of Stainless Steel Filler Wire

Excellent Weld Quality – Produces clean, smooth, and crack-resistant welds

High Corrosion Resistance – Performs well in chemical and aggressive environments

Stable Arc & Smooth Deposition – Ensures uniform weld beads

Consistent Diameter Control – Reliable performance during manual and automated welding

Strong Mechanical Properties – High tensile strength and durability

Low Hydrogen Content – Reduces risk of weld defects

SS Filler Wire Specifications

Wire Diameter Range: As per customer requirement

Grades Available: ER 308L, ER 309L, ER 310, ER 316, ER 316L, ER 347 & equivalent

Standards: AWS, ASTM, DIN, BS, JIS, NACE, GOST

Surface Finish: Bright, clean, and contamination-free

Form: Straight lengths or coils

Packaging: Moisture-protected, industrial-grade packing

Typical Applications of Stainless Steel Filler Wires

Stainless Steel Filler Wire from RWPL are used across multiple applications where weld quality and reliability are critical:

Fabrication & Structural Welding – Frames, tanks, and assemblies

Chemical & Process Industries – Pipelines, reactors, pressure vessels

Automotive & Railways – Components requiring strong, defect-free welds

Oil & Gas – Corrosion-resistant welding applications

Power & Heavy Engineering – Boilers, heat exchangers, and equipment

Customization & Supply Capabilities

RWPL offers custom SS Filler Wire solutions based on specific welding processes, base materials, and application requirements. We provide flexibility in wire grade, diameter, length, packaging, and order volume.

With consistent production capacity and timely deliveries, RATANAKAR Wire Private Limited ensures dependable supply and long-term performance for customers across domestic and international markets.

What is SS Filler Wire used for?

SS filler wire is used in welding applications to fill joints and create strong, corrosion-resistant welds in stainless steel fabrication, piping, pressure vessels, and structural components.

Which grades of Stainless Steel Filler Wire does RATANAKAR offer?

RATANAKAR manufactures Stainless Steel Filler Wire in commonly used grades such as ER 308L, ER 309L, ER 310, ER 316, ER 316L, ER 347, suitable for different stainless steel base metals and service conditions.

Is SS Filler Wire suitable for TIG and manual welding?

Yes. SS filler wire is widely used for TIG welding and manual welding processes where precise control, clean welds, and high joint strength are required.

How does SS Filler Wire differ from MIG wire?

Stainless Steel Filler Wire is mainly used for TIG and manual welding, whereas MIG wire is designed for continuous feeding in MIG welding machines. Filler wires offer greater control for precision welds.

Are RATANAKAR’s SS Filler Wire corrosion resistant?

Yes. Manufactured from high-quality stainless steel grades, our Stainless Steel Filler Wires provide excellent resistance to corrosion, heat, and chemical exposure.

Can RWPL supply customized SS Filler Wire specifications?

Absolutely. We offer customization in wire diameter, grade, length, and packaging to meet specific welding and industry requirements.