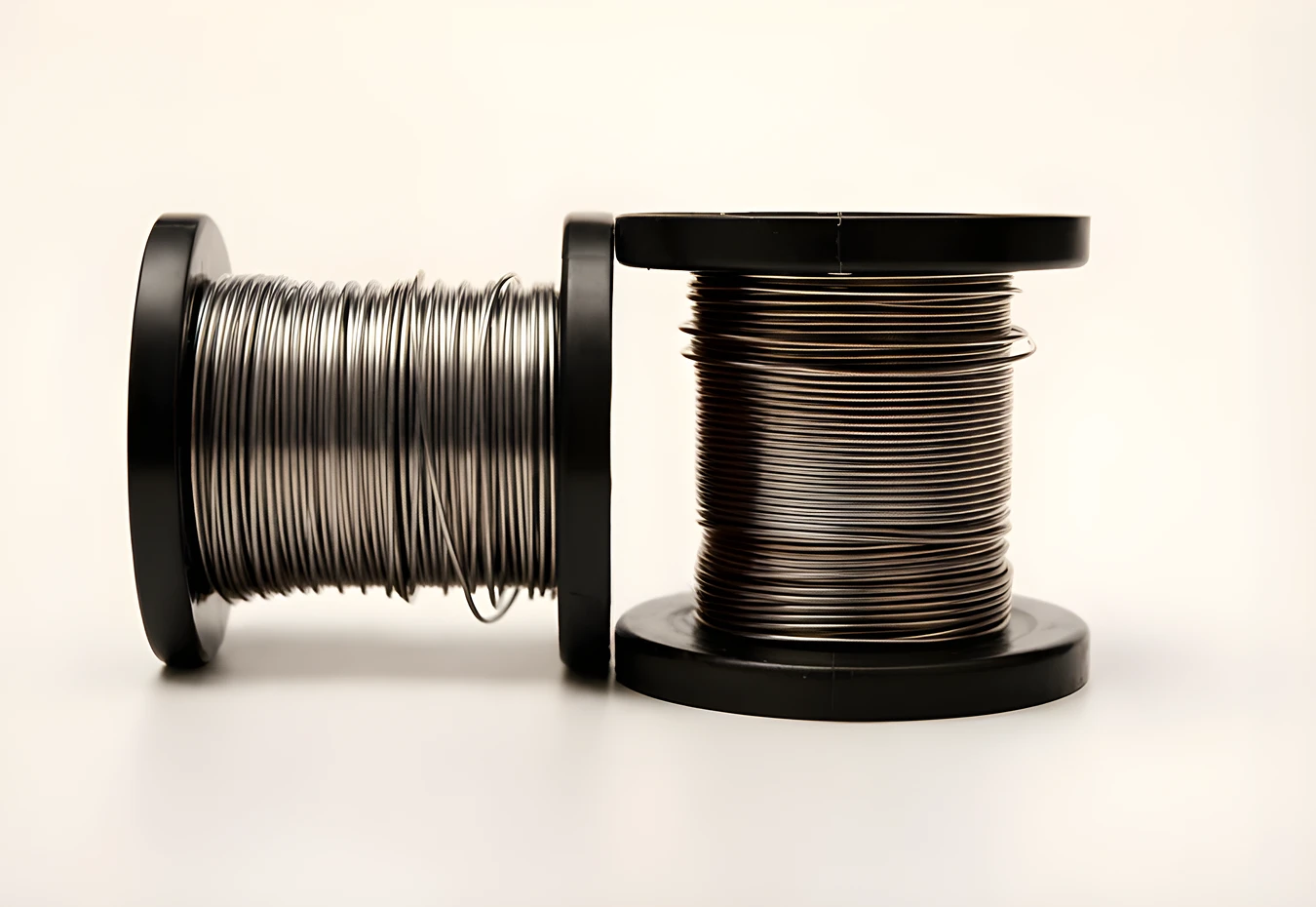

Stainless Steel Wire Spools

RATANAKAR Wire Private Limited (RWPL) is a reliable manufacturer and supplier of Stainless Steel Wire Spool engineered for smooth feeding, consistent performance, and long service life. Our wire spools are widely used in industrial, welding, fabrication, and automated applications.

A SS Wire Spool is made by uniformly winding high-quality stainless steel wire to ensure tangle-free operation, accurate dimensions, and efficient material usage, improving productivity in both manual and machine processes.

Manufacturing & Quality

At RWPL, ss wire spools are produced using advanced wire drawing and spooling machines for uniform tension, precise layering, and a smooth surface finish. Our in-house facilities include annealing, high-speed drawing, controlled winding, straightening, and cutting.

All products are manufactured in compliance with ASTM, DIN, BS, JIS, NACE, AWS, and GOST standards and follow an ISO 9001:2015 quality management system. We offer wire spools in AISI 201, AISI 202, AISI 304, AISI 304L, AISI 316, AISI 316L, AISI 321, AISI 430L and equivalent stainless steel wire grades, suitable for diverse industrial environments.

Key Features of Stainless Steel Wire Spool

Uniform Winding – Ensures smooth, uninterrupted wire feeding

High Tensile Strength – Maintains performance under continuous operation

Corrosion Resistance – Suitable for harsh, humid, and chemical environments

Smooth Surface Finish – Reduces wear on machines and tools

Consistent Diameter Control – Ensures precision in end applications

Low Material Wastage – Improves operational efficiency

Stainless Steel Wire Spool Specifications

Wire Diameter Range: As per customer requirement

Grades Available: AISI 201, AISI 202, AISI 304, AISI 304L, AISI 316, AISI 316L, AISI 321, AISI 430L

Spool Types: Plastic, metal, or customized spools

Standards: ASTM, DIN, BS, JIS, AWS, NACE, GOST

Surface Finish: Bright, matte, or customized

Packaging: Secure, moisture-protected industrial packing

Typical Applications

Our Stainless Steel Wire Spool products are widely used across multiple industrial applications due to their reliability and consistent quality:

Welding Applications – MIG welding and fabrication processes

Spring Manufacturing – Precision coiling and forming

Fasteners & Components – Bolts, clips, and formed parts

Automated Machinery – CNC, robotic, and continuous feed systems

General Engineering – Fabrication and assembly operations

Customization & Supply Capabilities

RWPL offers customized Stainless Steel Wire Spool solutions tailored to specific customer requirements. We provide flexibility in wire grade, diameter, spool size, winding pattern, surface finish, and packaging. Whether your application requires high precision, corrosion resistance, or continuous high-speed feeding, our wire spools are engineered for dependable performance.

With reliable production capacity and timely delivery, RATANAKAR Wire Private Limited supports industries with consistent supply and long-term quality assurance.

What is a Stainless Steel Wire Spool used for?

A Stainless Steel Wire Spool is used for controlled wire feeding in welding, electrical wiring, spring manufacturing, automated machinery, and fabrication applications.

Which grades are available in ss wire spools?

RATANAKAR offers wire spools in AISI 201, AISI 202, AISI 304, AISI 304L, AISI 316, AISI 316L, AISI 321, AISI 430L, depending on strength and corrosion resistance requirements.

Are Stainless Steel Wire Spools suitable for MIG welding?

Yes. Our ss wire spools are widely used for MIG welding due to their uniform winding, smooth feeding, and consistent diameter.

Can RWPL provide customized wire spools?

Yes. We offer customization in wire diameter, grade, spool type, winding pattern, and packaging based on customer needs.

How does RATANAKAR ensure wire spool quality?

Each wire spool undergoes tensile testing, dimensional checks, surface inspection, and process control under ISO 9001:2015 standards.